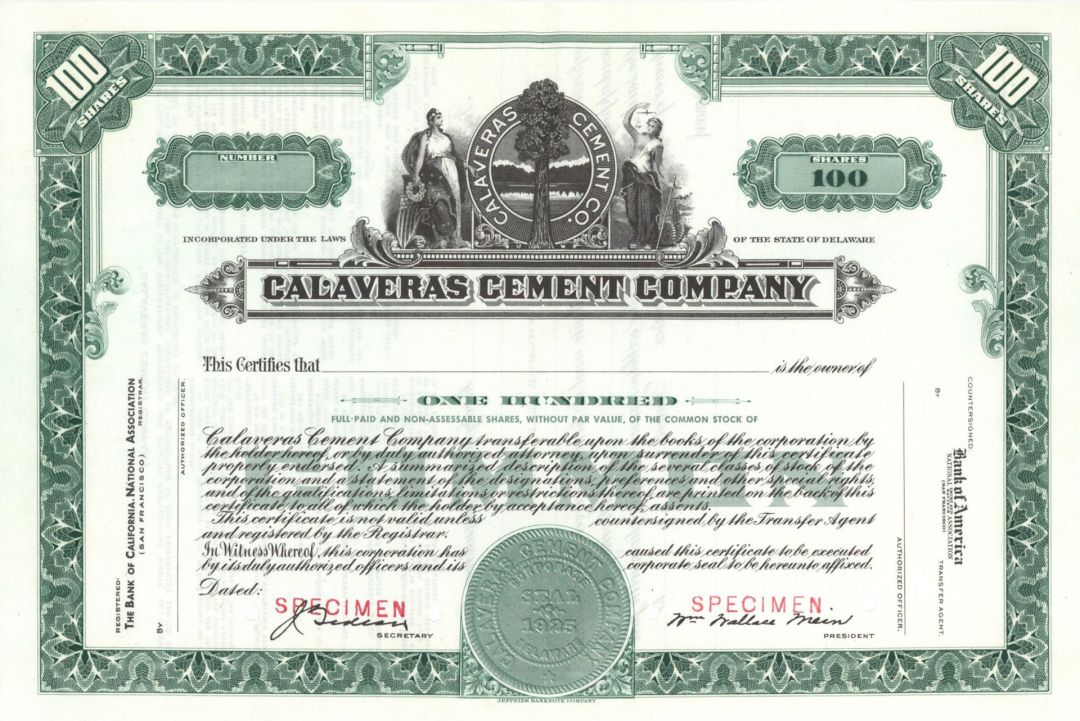

Calaveras Cement Co. - 1925 Specimen Stock Certificate

Inv# SE3727 Specimen StockDelaware

Specimen Stock printed by Jeffries Banknote Company. Please specify color.

Among the many landmarks along Highway 49 stands a railroad trestle, a reminder of a company prominent in Calaveras Countyâs industrial history for six decades. Travelers pass beneath the historic structure located about 2 miles south of San Andreas where the Calaveras Cement Co. established its plant following incorporation in 1925. The companyâs name was impressed into cement when the trestle was built in 1933 as part of a rail system linking several limestone quarries to the plant. Founder William Wallace Mein drew on his international mining and financial experience to raise $2 million ($31.8 million in todayâs dollars) through private stock sales to start the business. Purchase of extensive limestone deposits in the San Andreas area came first, followed by development of facilities to manufacture high quality cement from the quarried raw material. Twenty-five years later, annual production was at 1.3 million barrels of 376 pounds each and $3.50 per barrel in price. The plantâs ore crushers, blending and storage silos, kilns and thickening tanks were located just southwest of San Andreas along a Gold Rush wagon road to Calaveras County from Stockton. The Kentucky House, an historic stagecoach stop and trading post, was still standing and was restored by the company for offices, board meetings and hospitality. On May 6, 1926, the company was ready to begin production, but paused for an open house and barbeque that reportedly attracted 15,000 people, 2.5 times the countyâs entire population. A major infrastructure expense for shareholders was laying tracks to the Valley Springs railhead of the Southern Pacific to access distant markets. In 1940, the company spent over $1 million to switch the plantâs energy source from oil to cheaper natural gas by pipeline from Rio Vista 40 miles away. Business got off to a roaring start in 1927, with an order for 750,000 barrels of cement used in construction of the 358-foot-tall Pardee Dam on the nearby Mokelumne River. The Great Depression years brought projects such as OâShaughnessy Dam in Yosemite National Park, the first Broadway Tunnel connecting the East Bay to the San Joaquin Valley, San Francisco-Oakland Bay Bridge, Friant Dam on the San Joaquin River east of Fresno and San Franciscoâs Marina Jr. High School, which incorporated the companyâs newly introduced white cement. World War II saw major plant expansion to accommodate million-plus-barrel years generated by contracts at McClellan Field, Fairfield-Suisun airbase, Mare Island and Hunters Point naval depots and docks and Mather Field. Post-war activity kept the plant busy supplying cement to Central Valley Project canals, Pacific Gas and Electric Co.âs Cresta and Rock Creek dams and powerhouses on the Feather River, Oroville Dam, widening the highway over Altamont Pass and the east of Fresno Pine Flat Dam, which consumed 1.6 million barrels of Calaveras cement. Closer to home, the Parrots Ferry Bridge, one of the largest examples of segmented cantilever construction, used the same âhome-grownâ cement. In 1959, the company was sold to Flintkote Co. and 20 years later to Genstar, a Canadian company that shut down operations in 1983, unable to compete with cheaper prices from China and facing costly plant modernization. The San Andreas facility was demolished two decades later, but the Calaveras Cement Co. lives on for its part in building the West.

Stock and Bond Specimens are made and usually retained by a printer as a record of the contract with a client, generally with manuscript contract notes such as the quantity printed. Specimens are sometimes produced for use by the printing company's sales team as examples of the firms products. These are usually marked "Specimen" and have no serial numbers.

Ebay ID: labarre_galleries